Professional Finishing

Create mirror-finishes, unusual textures and exciting contrasts using both hand technuqies and power tools to achieve perfection in your finished creation.

Create mirror-finishes, unusual textures and exciting contrasts using both hand technuqies and power tools to achieve perfection in your finished creation.

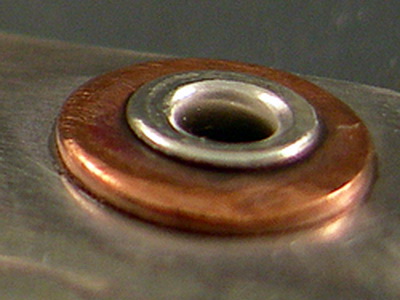

Many mechanisms and joints require movement and thus cannot be soldered or fused. Learn common cold joining techniques to combine different design parts by rivetting.

Apply traditional prong and bezel stone setting styles from first principles and understand the challenges of more advanced setting techniques such as channel, flush and pavé settings...

Practice gas torch soldering on different metals and understand metal and solder compatibilities. Also learn fusing, the process of bonding metals together at melting point without solder.

Practice with the use of steel punches to create textures; learn how to apply textures through the use of a rolling mill. For more unusual surface textures, master the technique of reticulation.